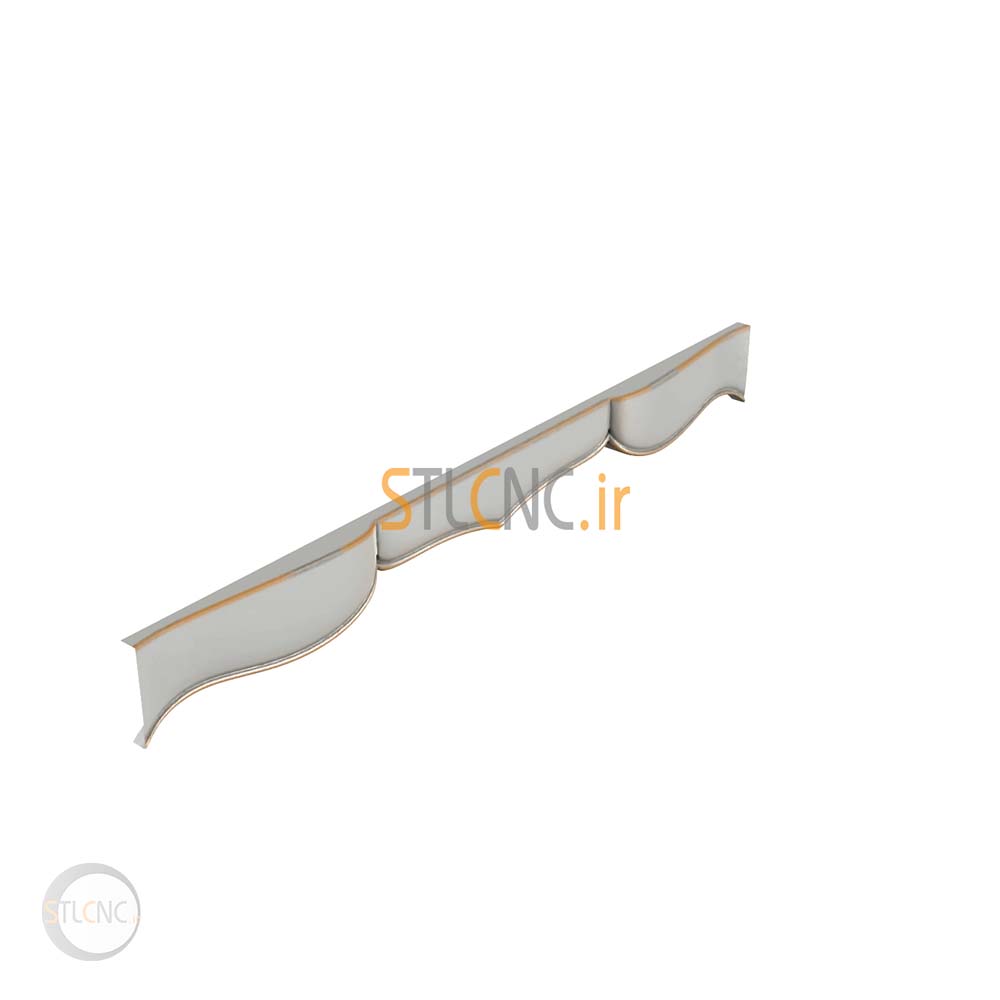

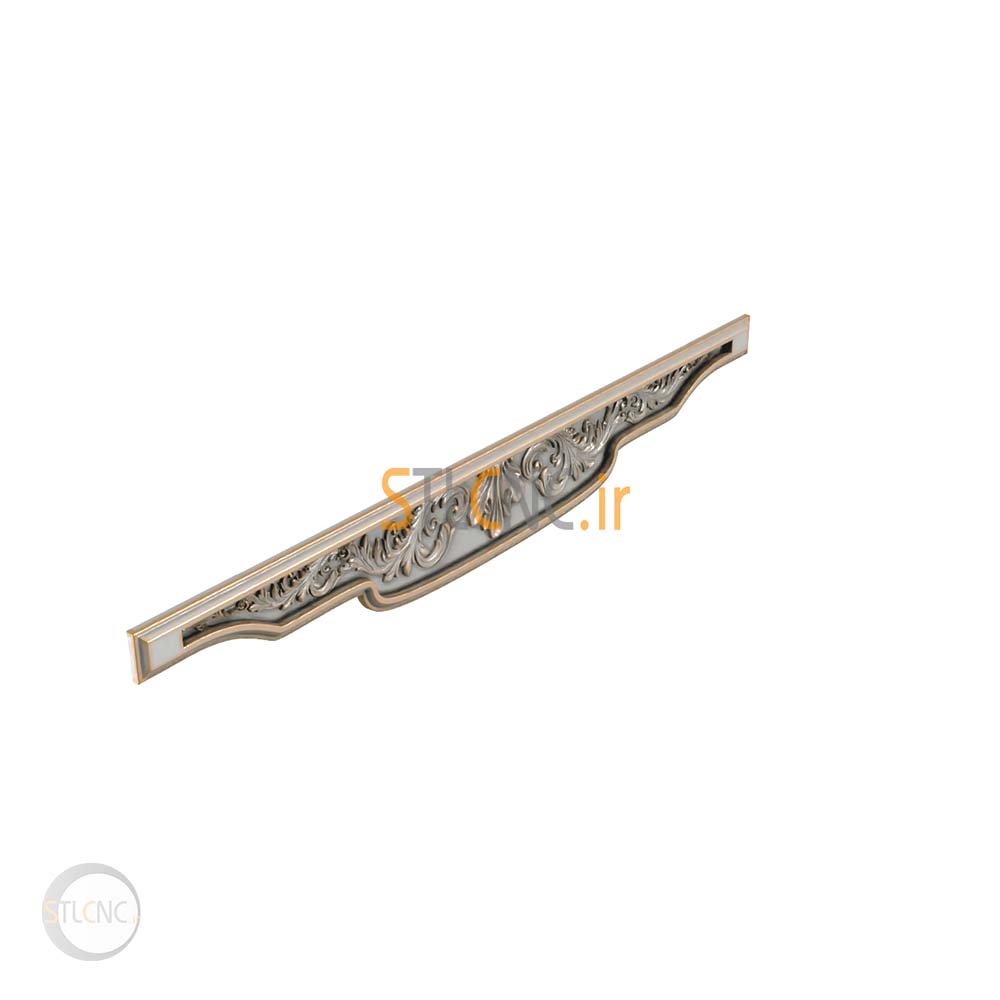

Underframes 3D Models UND-114

$4

After making an online payment, you will promptly receive the direct download link for the 3D file of this design.

| File format | STL |

| Ready to G-Code? | Yes |

| 3D printable? | Editing is required before printing. |

| Editable? | Yes, there is a need for software expertise. |

| STL file size | 50 MB |

| Dimensions | X=1000 Y=19 Z=114 |

| Mesh triangles | 1011218 |

| Mesh Vertices | 3033654 |

Site introduction:

Looking for high-quality Underframes 3D Models for your CNC projects? Our online store offers a wide selection of 3d files download , perfect for CNC enthusiasts.

With our files, you can easily create G-code using popular CAM programs such as PowerMill, ArtCAM, and more. Whether you’re a beginner or an experienced user, our user-friendly files and compatibility with various CAM programs make the CNC process a breeze. Start exploring our collection of 3D files today and bring your CNC projects to life with ease!

About Underframes 3D Models:

With our underframe 3D models, you can explore the historical evolution of underframes in art and production. From traditional wooden frames to modern metal structures, our models showcase the diverse range of underframe designs throughout history.

This underframe 3D models offer a valuable resource for your projects. Our models are compatible with popular 3D design software and can be easily integrated into your workflow.

You can customize and modify the models to suit your specific requirements, ensuring a seamless transition from concept to production. Discover the possibilities of underframes in art and production with our extensive collection of 3D models.

Useful information about 3d files download:

Looking for a convenient way to generate G-code from your STL files? With our easy-to-use software and step-by-step guide, you can quickly and efficiently convert your 3D files into G-code using PowerMill.

PowerMill is a powerful CAM (Computer-Aided Manufacturing) software that simplifies the process of creating toolpaths and generating G-code for CNC machines. It offers a comprehensive set of tools and features specifically designed for machining complex 3D models. To generate G-code from your STL file using PowerMill, simply follow these steps:

1. Import your STL file into PowerMill.

2. Set up your machining parameters, such as tool selection, cutting strategies, and feed rates.

3. Use PowerMill’s intuitive interface to define your toolpaths, including roughing, finishing, and detailing operations.

4. Verify and simulate your toolpaths to ensure accuracy and identify any potential issues.

5. Once you’re satisfied with the toolpaths, generate the G-code. With PowerMill’s advanced capabilities, you can optimize your toolpaths for efficiency, precision, and surface finish quality. It also provides options for customizing the G-code output to match your specific CNC machine requirements.

Start maximizing your productivity and achieving superior results with our 3D files download and PowerMill. Empower your CNC machining process by seamlessly converting your STL files into G-code.

Download our files today and unlock the full potential of PowerMill!

| CNC Type | 3-Axis |

|---|---|

| Overall Shape | Non-geometric |

| Quality | Medium |

Related products

Underframes

Underframes

Underframes

Underframes

Underframes

Underframes

Underframes

Underframes